Collapse

Please log in to your account to view your subscribed posts.

| Directory | Topics | Posts | Last Post | ||||||

|---|---|---|---|---|---|---|---|---|---|

|

3D Printing

Here is a place specifically for information and questions relating to 3D printing. If you're doing a full buildup, I highly recommend putting that under the relevant section and reserving posts relating specifically to the 3D printing aspect for this area.

Topics: 45

Posts: 448

|

45 | 448 | |||||||

|

Forum Software Questions and Comments

Got an issue with how the forum is behaving for you? Have a technical issue you need some help with? Here is where to post up the issues!

Topics: 45

Posts: 373

Last Post:

|

45 | 373 | |||||||

|

GENERAL TOPICS

General Interest R/C Model Building Topics

Topics: 2,238

Posts: 27,361

Last Post:

|

2,238 | 27,361 | |||||||

|

Local Area Sub Drivers

This is the area to post up information, banter and general blathering specific to your regional area. If you have a group of local people and find a need or desire to have an area for you to chat in, drop me a line at bob@rc-sub.com and I'll get you hooked up!

Topics: 26

Posts: 134

Last Post:

|

26 | 134 | |||||||

|

Sub-Forums:

| |||||||||

|

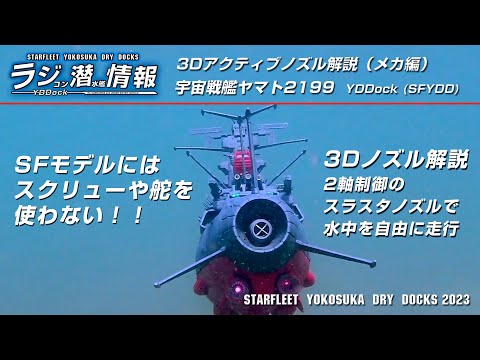

Photos of Concept, Fantasy or Science Fiction Subs

Not all RC subs are of real boats! Post up your favorite CG, concept, fantasy, or science fiction submarines here and let the "experts" decide if it will work or not...

Topics: 14

Posts: 131

Last Post:

|

14 | 131 | |||||||

|

PHOTOS OF REAL SUBS

This forum is dedicated to photos of actual submarines from navies around the globe. Please choose the correct sub-forum for the photos you would like to post, and be sure to create the new topic with the correct class of submarine for easy searching later.

Topics: 77

Posts: 343

Last Post:

|

77 | 343 | |||||||

|

Sub-Forums:

| |||||||||

|

RC Submarine Radios

This is the place to find information about the radios used in RC submarines.

Topics: 10

Posts: 85

Last Post:

|

10 | 85 | |||||||

|

Sub-Forums:

| |||||||||

|

Way Off Topic

Here is where all of us can feel free to post up (almost) anything and everything that is interesting, frustrating, enlightening or otherwise thought to be of interest to the bubbleheads that hang out here.

Rules of the road: Common sense rules here. No cussing. No attacking people on their viewpoints. No racial slurs or hate speech. Have at it.

Topics: 16

Posts: 112

Last Post:

|

16 | 112 | |||||||

|

Nautilus Drydocks Products

Questions and Answers for products sold by the Nautilus Drydocks

Topics: 242

Posts: 2,473

Last Post:

|

242 | 2,473 | |||||||

|

Sub-Forums:

| |||||||||

|

SILLY QUESTIONS FROM NEWBIES!

Here you can expect to be chastized, laughed at, put through the ringer by his Eminence, and made to feel thoroughly stupid for asking daft questions! Go for it!

Topics: 485

Posts: 3,723

Last Post:

|

485 | 3,723 | |||||||

|

TIPS'N TRICKS

Post your latest neat idea here. How you fixed the woffle sprocket on the doofer! Or painted on a coat on invisible paint. We nee to know, you need to share.

Topics: 140

Posts: 1,028

Last Post:

|

140 | 1,028 | |||||||

|

Builder Threads

We welcome all your projects here, regardless of the model manufacturer.

You can upload photographs to your own album and display them here.

Topics: 649

Posts: 25,128

Last Post:

|

649 | 25,128 | |||||||

|

Sub-Forums:

| |||||||||

|

Technical Support and Tips

Technical Support from your product suppliers

Topics: 230

Posts: 1,694

Last Post:

|

230 | 1,694 | |||||||

|

Sub-Forums:

| |||||||||

|

Model Building Equipment

Discuss Sub-Drivers, WTCs, RCABS, Snort, Radios, Receivers, Power Supplies and accessories here.

Topics: 106

Posts: 1,005

Last Post:

|

106 | 1,005 | |||||||

|

The Scrap Yard -- BUY & SELL HERE!

Old 'sardine cans', pig boats, unwanted models, motors, stuff and general submarine stuff.

Buy, sell and trade it here.

No commercial advertising.

And don't come bitching to us if your deal doesn't work out.

Topics: 321

Posts: 1,556

Last Post:

|

321 | 1,556 | |||||||

|

I.D. THIS!

Here's an opportunity to post photos of those odd-ball submarines of yore, or try your skills at identifying your colleagues submissions.

Topics: 93

Posts: 1,820

Last Post:

|

93 | 1,820 | |||||||

|

EVENTS AND REGATTAS

Information about past, current and upcoming events in the R/C submarine community.

Topics: 69

Posts: 732

Last Post:

|

69 | 732 | |||||||

|

TORPEDOES

Our very popular torpedo system warrants it own forum.

We'll try to keep all information for any model carrying a torpedo system on one thread here.

Topics: 38

Posts: 727

Last Post:

|

38 | 727 | |||||||

|

ROVs Remotely Operated Vehicles

We've had a number of people interested in these vehicles, so it seems like a good idea to start special forum for it.

Post away!

Topics: 10

Posts: 46

Last Post:

|

10 | 46 | |||||||

|

TARGETS!

Some of us build stuff that submarine skippers should smack their lips at when seen through a periscope, so post your builds of these morsels for us to gloat over please.

Topics: 123

Posts: 1,517

|

123 | 1,517 | |||||||

|

Sub-Forums:

| |||||||||

|

YOUTUBE VIDEOS

Please put a link here to your favorite Youtube submarine video

Topics: 312

Posts: 1,142

Last Post:

|

312 | 1,142 | |||||||

|

David Merriman's Cabal Reports Etc

Read David Merriman's Cabal Reports Here.

Topics: 69

Posts: 956

Last Post:

|

69 | 956 | |||||||

|

ROGUES GALLERY

Put a face to the name, post up your info and let us know: "Who the hell are you, and why are you breathing my air?"

(Standard question on US submarines to new recruits.)

Topics: 38

Posts: 337

Last Post:

|

38 | 337 | |||||||

|

Sub-Forums:

| |||||||||

|

REFERENCE LINKS

Post links to Internet sites containing plans, photos, and specifications.

WIKIPEDIA.COM is an excellent reference point.

Topics: 25

Posts: 80

Last Post:

|

25 | 80 | |||||||

What's Going On

Collapse

There are currently 391 users online. 2 members and 389 guests.

Most users ever online was 2,067 at 06:42 AM on 11-18-2023.

The Sub-drivers Forum Statistics

Collapse

Topics: 5,450

Posts: 72,951

Members: 1,837

Active Members: 45

Welcome to our newest member, Eaten0523.

Latest Topics

Collapse

-

What is the best ballast system for an ARK 1/48 type VII U boat? I am thing about buy one... Is a piston tank the best? THANX

-

Channel: GENERAL TOPICS

-

-

-

by DavjacvaMerriman e-mailed me a few weeks ago telling me that something arrived for me in his mail from our buddy Fred Freketic up in Massachusetts and he said...

-

Channel: Builder Threads

-

Recent Blog Posts

Collapse

There are no results that meet this criteria.